Description

1. Chain Size and Classification:

- 28B refers to the size of the chain:

- 28 indicates the pitch, which is the distance between the centers of two adjacent pins. For the 28B chain, the pitch is typically 7/8 inch (or 22.23 mm).

- B designates a specific style of chain that is usually equipped with hardened steel rollers and pins, offering superior wear resistance and strength.

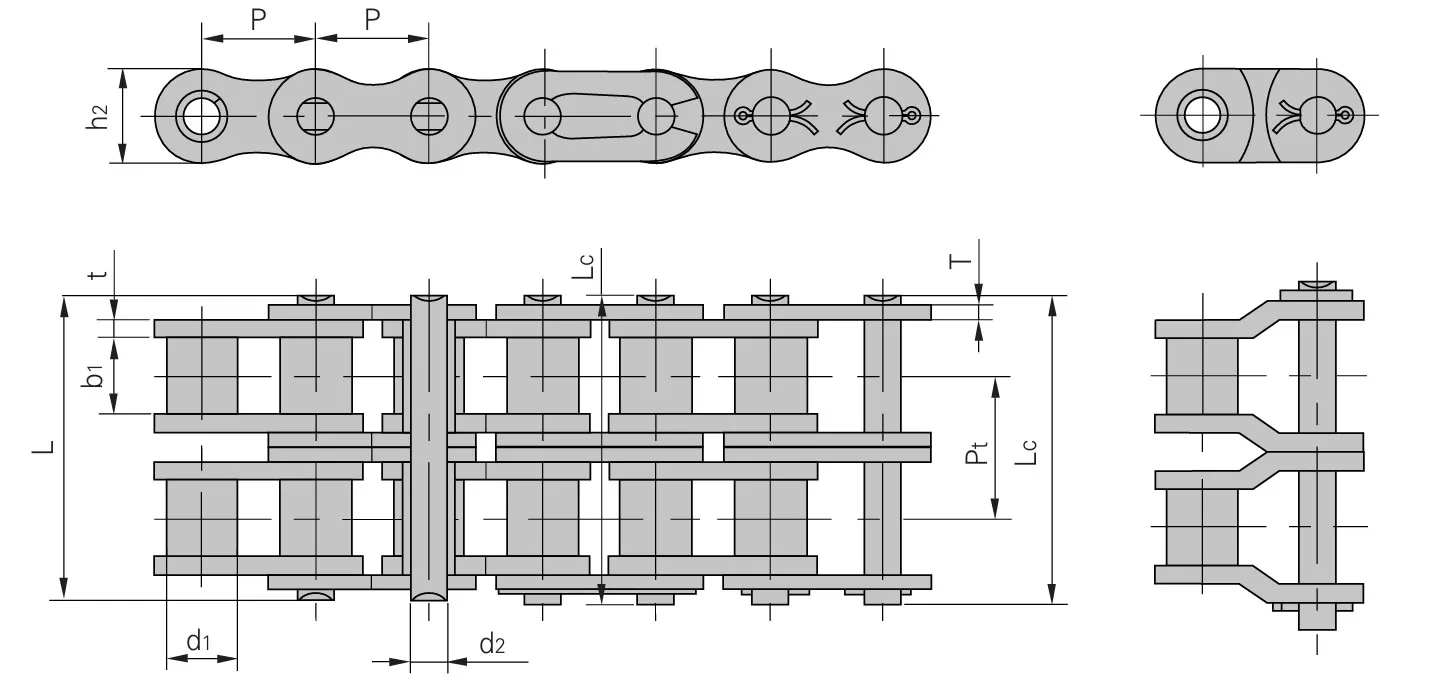

2. Duplex Chain:

- Duplex means that the chain has two rows of rollers, which provides several key benefits:

- Higher Load Capacity: The duplex design enables the chain to handle more load than a Simplex chain (which has only one row of rollers). This makes the 28B-2 chain suitable for medium-to-heavy-duty applications.

- Improved Durability: The additional row of rollers distributes the load more evenly, which reduces wear and tear, leading to a longer service life, especially in high-stress environments.

3. Common Applications:

- The 28B-2 Duplex roller chain is typically used in a wide range of industrial and mechanical applications that require high strength, reliability, and durability:

- Industrial machinery: In applications such as conveyor systems, assembly lines, and other heavy-duty equipment.

- Power transmission systems: For systems that need to handle higher loads and offer dependable performance over time.

- Automated systems: In machines and mechanical systems requiring consistent and efficient power transmission.

- Heavy-duty equipment: In industries such as construction, agriculture, mining, and manufacturing, where equipment operates under substantial stress.

4. Material and Construction:

- Steel: The 28B-2 roller chain is typically made from high-strength steel, ensuring durability and resistance to wear.

- Corrosion Resistance: Certain versions of the chain may feature corrosion-resistant coatings such as zinc plating, making it suitable for outdoor and corrosive environments.

- Heat Treatment: The components of the chain, such as rollers and pins, are often heat-treated to improve their hardness and resistance to wear.

- Lubrication: Proper lubrication is essential to ensure smooth operation, minimize friction, and extend the chain’s service life.

5. Dimensions:

- The 28B-2 Duplex roller chain typically features:

- Pitch: 7/8 inch (22.23 mm), which is the standard distance between the centers of adjacent pins.

- Duplex design: The chain has two rows of rollers, allowing it to carry heavier loads compared to Simplex chains.

6. Advantages of Duplex Chains:

- Higher Load Capacity: The duplex design allows for more efficient handling of higher loads compared to simplex chains. The 28B-2 chain is well-suited for applications that demand more strength.

- Increased Durability: The two rows of rollers help distribute the load more evenly, reducing wear and improving the overall durability of the chain.

- Reduced Maintenance: Because duplex chains are stronger and more durable, they generally require less maintenance than simplex chains, reducing downtime and costs.

- Efficient Power Transmission: The duplex chain provides reliable and efficient power transmission, even in high-load applications, ensuring smooth and consistent operation.

Bearings Specialist Co.,Ltd. was founded in 1999 and has since emerged as a premier supplier of bearings and power transmission components in the Thailand automotive and industrial market place. We offer a wide range of products from leading brands. Our partners include TIMKEN, REXNORD, RENOLD, OPTIBLET, NSK, NIS, FENNER, FALK and MOMENTUM

Our Bearings and Industrial Power Transmission Components are used in a variety of industries, including Cement, Construction, Food & Beverage, Mining, Oil & Gas, Palm Oil, Power Plant, Pulp & Paper, Semiconductor manufacturing, Steel, and Mining.

We supply and distribute wide ranges of Bearings, Transmission and Conveyor Chains, Oil seals, Transmission Belts and Pulley, Shaft couplings, Gear Drives, Maintenance Tools and many more.

The key to our continued growth and success lie on our commitment to become the most preferred business partners by providing reliable solution to our customer through the products we distribute and services we provide.

Our commitment, to enhance customer satisfaction is our priority, by creating values for our customer through deep understanding of each application is our greatest assets.